- Biochar characterization and quality control

- Custom filter system design and pilot testing

- Life-cycle and cost analysis for scale-up feasibility

The US Midwest faces significant challenges from nitrogen fertilizer runoff. Excess nitrogen leaches into rivers, contributing to hypoxic “dead zones” in the Gulf of Mexico and contaminating rural drinking water with high nitrate levels. Iowa alone accounts for approximately 25% of the nitrogen load fueling Gulf hypoxia.

Globally, over 2 billion people lack access to safe drinking water, with contamination from heavy metals, nitrates, PFAS, and organic poullutants. Biochar offers an innocative solution at both ends" reducing nutrient runoff from agriculture and purifying water supplies.

Over 2 billion people globally lack access to safe drinking water, with contamination from heavy metals, nitrates, organic pollutants, and emerging contaminants like PFAS increasingly common.

Effluents, agricultural runoff, and unregulated waste disposal contribute to widespread water insecurity. Innovative and decentralized solutions are urgently needed to address both urban and rural contamination challenges.

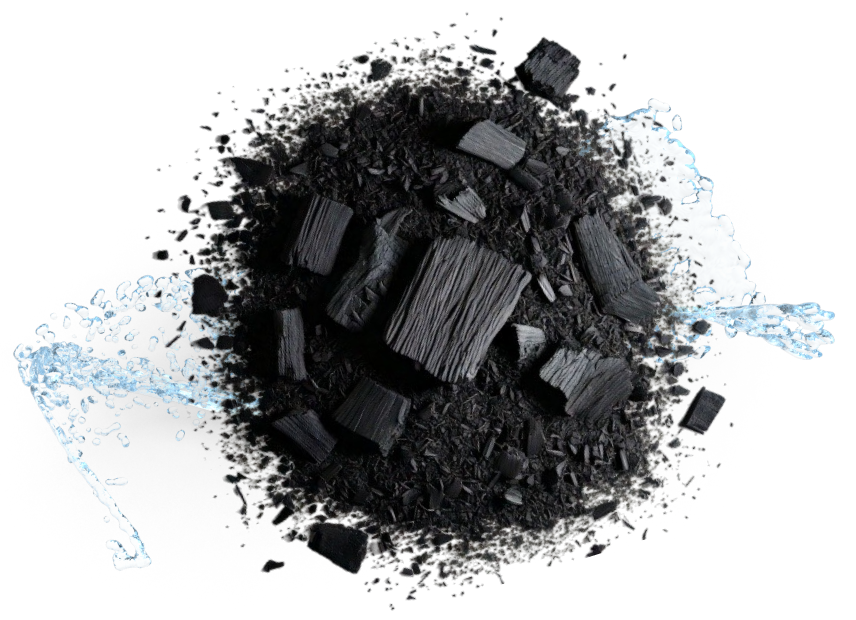

Biochar is a stable, porous, carbon-rich material produced via pyrolysis of biomass waste. It enhances soil amendment, water retention, nutrient holding capacity (CEC), and pH buffering.

It also represents a circular economy tool, turning agricultural residues into valuable soil amendments and contributing to carbon sequestration.

Meta-analyses and field studies demonstrate high contaminant removal efficiencies using biochar:

| Contaminant | Biochar Removal Efficiency |

|---|---|

| Lead (Pb) | 90–99% |

| Arsenic (As) | 85–95% |

| Nitrate (NO₃⁻) | 50–80% |

| Phosphates (PO₄³⁻) | 60–90% |

| E.coli | 40–80% |

Field trials in the Midwest demostrated:

Engineered biochars can be tailored for specific contaminants using surface modification techniques or by co-pyrolizing with minerals such as Mg or Fe oxides.

Our Techno-Economic Analysis (TEA) and Life Cycle Assessment (LCA) provide critical insights into the return on investment (ROI) and carbon reduction potential of these applications.

FAO. (2023). The State of Food and Agriculture: Water Pollution. Food and Agriculture Organization of the United Nations.

Mohan, D., Pittman, C. U., & Steele, P. H. (2006). Adsorption of arsenic, cadmium, and lead by chars produced from fast pyrolysis of wood and bark. Environmental Science & Technology, 40(3), 928–934.

USEPA. (2022). Contaminants of Emerging Concern including PFAS. U.S. Environmental Protection Agency.

Yuan, P., Wang, J., Pan, Y., Shen, B., & Wu, C. (2019). Review of biochar for the removal of pollutants from aqueous solutions. Chemosphere, 221, 635–658.

Zhang, W., Mao, S., Chen, H., Huang, L., & Qiu, R. (2013). Pb(II) and Cr(VI) sorption by biochar derived from municipal sewage sludge: The role of surface functional groups and pore structure. Bioresource Technology, 136, 374–379.

Rabalais, N. N., Turner, R. E., & Wiseman, W. J. (2002). Gulf of Mexico hypoxia, aka "The Dead". Annual Review of Ecology and Systematics, 33, 235-263.

Mukherjee, A., Zimmerman, A. R., & Harris, W. (2011). Surface chemistry variations among a series of laboratory-produced biochars. Geoderma, 163(3-4), 247-255.